General information

FINAL S.A. is a modern and dynamic company with over 20 years of experience in the production of aluminium profiles, lacquering with the use of the newest trends, and in prefabricating. The company's registered office is located in Katowice Special Economic Zone, in Sosnowiec-Dąbrowa Subzone.

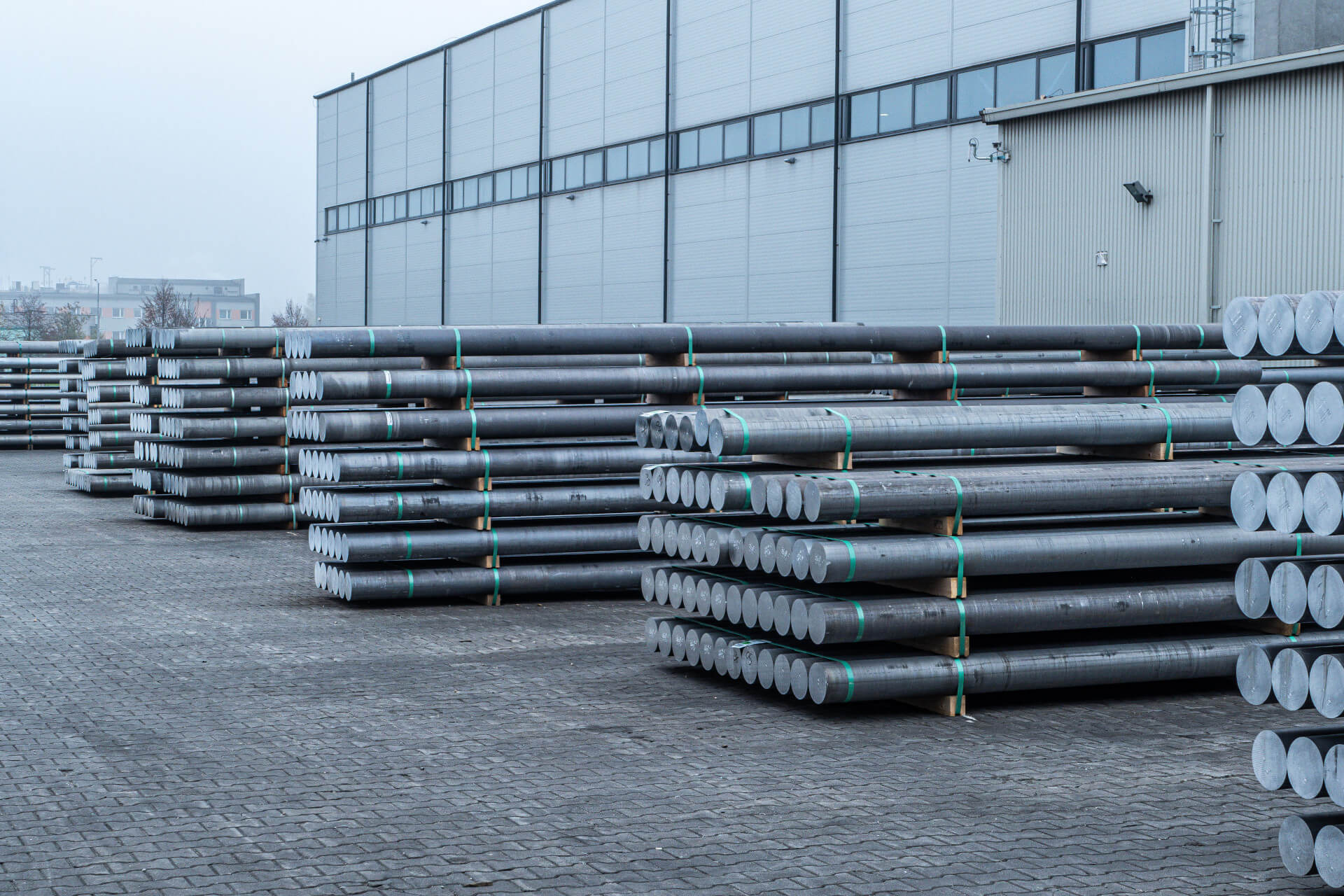

The company is specialised in the production of extruded profiles from the best quality aluminium alloys as well broadly understood processing. Our offer covers various products made of aluminium, which are intended for such industries as construction, machinery, automotive, or industries related to interior design and the introduction of the newest architectonic solutions.

The use of innovative technologies, professional machinery, and engaging experienced specialists are our strengths thanks to which we can meet even the most complex challenges presented to our teams. Aluminium profiles are manufactured on three modern production lines equipped with the press with a capacity of 2000 tons, 1800 tons, and 1600 tons, respectively.

Our annual production capacity is as much as 26 thousand tons of aluminium profiles. Our lines are equipped with control systems enabling fully automated operation cycles. We utilize a pyrometric system for measuring the temperature of the charge and extruded profiles, system for the generating the protective atmosphere around extruded profiles, and cooling systems.

In our production, we use aluminium alloys series 1070, 6060, 6063, 6005, and 6082 with the chemical composition compliant with PN-EN 573-3. The use of high-quality raw material allows us to manufacture the best-class finished goods with strength properties in conformity with the requirements of PN-EN 755-2 for class T4 to T66.

Our priority is to provide comprehensive services with regards to the production of aluminium profiles. This led to the launch of the machining CNC centre allowing us to perform virtually every aluminium processing operation (cutting, drilling, milling, die-cutting, etc.). For samples we use machines and equipment from recognized and valued European manufacturers, where the maximum length of aluminium profiles on CNC centres is 7.7 m and the measurements of profiles are 275 x 210 mm.

To adjust to the customer requirements and the changing market, our offer has been extended by a powder coating of aluminium profiles in a full RAL range of colours, all types of gloss, powder coating structures, and metallised coating. The construction of a separate line allowed us to offer wood-like surface coating, which has been by far the most popular in recent years. This wood-like treatment can be applied to profiles that are up to 7 meters long. The result is an aesthetic and resistant coating imitating natural wood.

Transport of ordered aluminium profiles is consulted with the client and adjusted to their needs. Depending on customer requirements, each batch of profiles is packed in basic units, such as baskets, cardboard boxes, pallets, or collective packaging. The way the profiles are placed in a cardboard box, the type and number of spacers are adjusted to the safety requirements during transport so that products reach the destination place without any damages.

The high quality of products and services as well as environmental responsibility are ensured by our certified management systems compliant with PN-EN ISO 9001:2015 and PN-EN ISO 14001:2015.

The implementation of innovative technologies and testing the newest solutions allow us to be updated about every novelty, thanks to which manufactured aluminium profiles can be fully compliant with requirements.

We guarantee you high-quality products, timely performance, attractive prices, and professional service.