Offer

We ensure high product quality, timely order fulfillment, competitive prices, and professional service.

We produce aluminum profiles with respect for the natural environment, supporting sustainable development. Collaborate with us and genuinely support environmental protection by choosing products made in an ecologically responsible manner. Together, we can help shape a more sustainable future.

Offer

FINAL is a modern aluminum profile extrusion plant located in the southern part of Poland.

Industries

Products and Services

FINAL for Your Industry

Trucks, trains, boats, cars. Their manufacturers use FINAL aluminum profiles. Why? Because they are durable and lightweight. This affects the safety of passengers and goods. It also guarantees lower fuel consumption and CO2 emissions. FINAL aluminum profiles are used by manufacturers of trailers, truck and van bodies, cargo securing systems, hinges, as well as loading ramps and platforms.

Frameworks, facades, railings, scaffolding. No large building could be constructed without aluminum profiles. Aluminum profiles are durable and lightweight. Construction cannot begin without them. Construction and architectural firms know this. That's why FINAL aluminum profiles are a popular choice for building structures and finishes.

Furniture, lamps, radiators, shower cabins, everyday objects - aluminum profiles can be found almost everywhere. Items made of aluminum guarantee durability as they do not wear out quickly, unlike wood. They are also aesthetic and beautiful. Their advantage over natural materials is that they can take any shape and color.

Soundproofing screens, signs, telecommunication masts and antennas, internal transport systems. Strong yet lightweight materials are required for their construction. That’s why FINAL aluminum profiles are the best choice. They ensure high quality of the constructed elements. The advantage of the profiles produced at our facility is their ease and speed of installation. This translates into lower costs and shorter installation times.

Rails, support structures, mounts, frames. The delicate nature of photovoltaic systems requires strong, lightweight, and weather-resistant materials. FINAL produces such profiles. Companies installing photovoltaic systems turn to our aluminum panels. They appreciate the high quality and attention to detail, which helps them with precise panel installation.

Panels, gates, fences, and mounting elements made from aluminum panels are a superior alternative to traditional fencing. They are not only durable and weather-resistant but also aesthetic. Unlike traditional fences, they do not require frequent maintenance or repainting. Companies that install aluminum panel fences value the ease and speed of FINAL’s installation, which leads to lower construction costs.

Responsibility

FINAL and Sustainable Development

FINAL Ingots and CO2 Emissions

You care about the environment. You run your business with future generations in mind. You choose products whose production does not negatively impact the planet. We invite you to collaborate with us. FINAL is a socially responsible company that cares about the future.

We take care of the environment and consciously reduce greenhouse gas emissions, including carbon dioxide. In our offer, you have four types of inserts to choose from, produced using energy from renewable sources or with reduced CO2 content made from recycled aluminum.

Post-Industrial Scrap

For the production of aluminum profiles, we use defective products. These are products that were created during the manufacturing process of our partners and could not be sold. They are collected, sorted, and recycled by FINAL’s suppliers. Then they come to us and are included in the production process of our aluminum.

Post-Consumer Scrap

These are materials that have been used up and can no longer serve their purpose. Examples include cans, old window frames, and construction materials. They are collected, sorted, and recycled in homes, factories, and companies.

The aluminum produced from these materials is the most environmentally friendly. We use it to manufacture cans, bicycles, and cars. This process results in nearly zero greenhouse gas emissions.

Gallery

The experience and technological knowledge of employees, allows FINAL to provide each client with the support and technical consulting services as well as support in profiles designing.

Potential and present clients have access on the company’s website to information concerning production possibilities, available aluminium alloys, mechanical processing possibilities, as well as possibilities of refining aluminium profiles surface.

Individual approach to each client and each project is crucial to Final S.A.

Numbers

Final in numbers

+500

active clients

+245000

tons of aluminium produced

+378

employees

Our mission

Caring for the environment, we create comprehensive aluminum solutions that ensure comfort and safety.

Final is a leader in the aluminum industry. We are a partner commonly chosen by entrepreneurs who use aluminum materials.

We produce our aluminum using the latest technology and with care for the environment.

Orders

Individual Orders with Your Idea

Present your idea, and we will propose possibilities and solutions.

Step 1

We listen to the client's needs and together consider how we can best assist in achieving them. We gather detailed information regarding the project, timelines, and specific requirements (technical specifications, schedule, budget). Then, we analyze this data, taking into account our technological and post-production capabilities. We strive to find a compromise that considers the interests of both parties, ensuring that the final result is satisfying for both the client and us.

Step 2

We develop a preliminary outline of the solution based on the collected information. In a team of specialists, we discuss various approaches to the production process of aluminum profiles and choose the most efficient one. We present the initial visualizations and technical specifications to ensure that our vision aligns with the client's expectations.

Step 3

We present a detailed action plan, taking into account all technical and logistical aspects related to the extrusion of aluminum profiles. We provide complete project specifications, schedules, and cost estimates. We conduct consultations to ensure that all client needs and requirements are met.

Step 4

We listen to the problem and consider how we can help solve it. We gather information about budget, timeline and requirements.

step 5

After completing the development phase, we begin the production of aluminum profiles according to the established plan. We provide full technical support at every stage of order fulfillment. We offer additional services such as cutting, drilling, milling, stamping, and surface finishing, including anodizing, powder coating, and wood-like coating application. We finalize the process by delivering products tailored to the client's requirements, ensuring safety during transport and quality that meets expectations.

Step 1

We listen to the client's needs and together consider how we can best assist in achieving them. We gather detailed information regarding the project, timelines, and specific requirements (technical specifications, schedule, budget). Then, we analyze this data, taking into account our technological and post-production capabilities. We strive to find a compromise that considers the interests of both parties, ensuring that the final result is satisfying for both the client and us.

Step 2

We develop a preliminary outline of the solution based on the collected information. In a team of specialists, we discuss various approaches to the production process of aluminum profiles and choose the most efficient one. We present the initial visualizations and technical specifications to ensure that our vision aligns with the client's expectations.

Step 3

We present a detailed action plan, taking into account all technical and logistical aspects related to the extrusion of aluminum profiles. We provide complete project specifications, schedules, and cost estimates. We conduct consultations to ensure that all client needs and requirements are met.

Step 4

We listen to the problem and consider how we can help solve it. We gather information about budget, timeline and requirements.

step 5

After completing the development phase, we begin the production of aluminum profiles according to the established plan. We provide full technical support at every stage of order fulfillment. We offer additional services such as cutting, drilling, milling, stamping, and surface finishing, including anodizing, powder coating, and wood-like coating application. We finalize the process by delivering products tailored to the client's requirements, ensuring safety during transport and quality that meets expectations.

News

Stay up

to date

Final S.A. Goes Green: The New Era of Eco-Friendly Aluminum Profiles

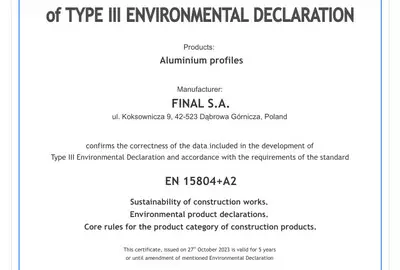

Certificate of Type III Environmental Declaration

Contact

Do you have questions

or want more details?